What you need to do to upgrade your jet ski boost system?

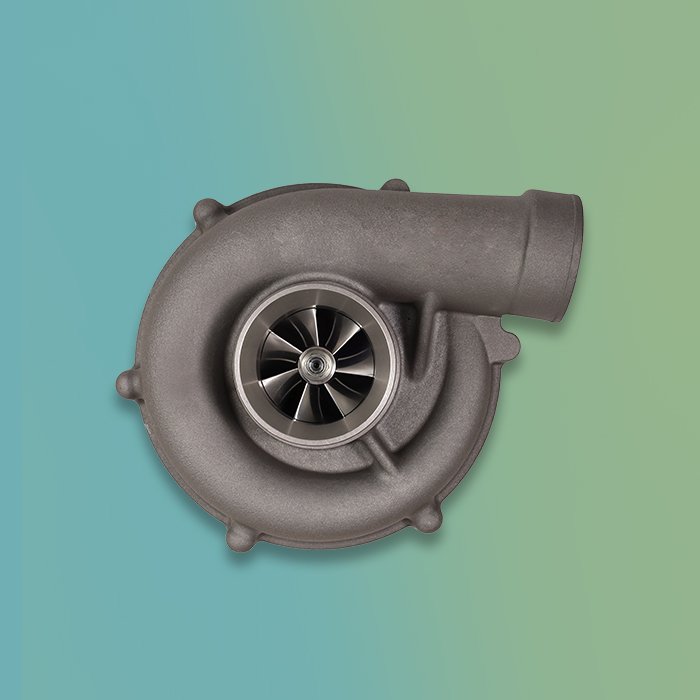

Upgrading a jet ski’s supercharger system is a complex task that requires specialised skills and experience. A supercharging system is used to increase the intake air density of the engine, providing more oxygen and fuel, which in turn allows the engine to produce a greater power output. This can significantly improve the performance of your jet ski, but it also puts more stress on the engine and other components, so it must be handled with care. Below are the steps to generally upgrade your jet ski’s supercharger system:

1. Determine the applicable pressurisation system

First, you need to identify the turbocharging system suitable for your personal watercraft model and engine. Different personal watercraft models and brands may require different types of turbocharging systems, so you must select a system that is compatible with your vehicle.

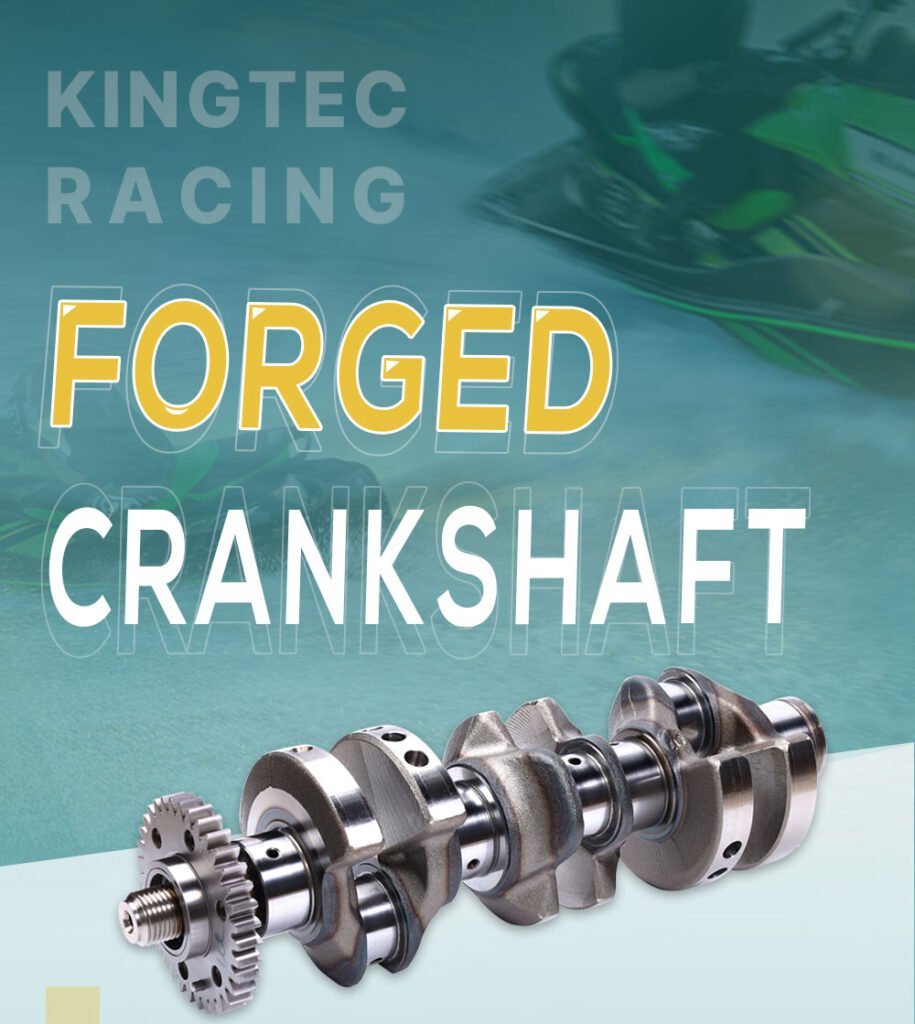

2. Acquiring the upgrade kit:

Purchase a turbocharging system upgrade kit that fits your personal watercraft model. Typically, this kit includes a turbocharger, intake pipes, exhaust pipes, turbocharging controller, fuel injectors, sensors, and other components.

3. Disassembling existing components:

Before installing the new turbocharging system, you should disassemble the current intake pipes, exhaust pipes, and other relevant parts. Ensure that you have the proper tools and safety equipment, and strictly follow the maintenance manual or manufacturer’s guidelines.

4. Installing the new turbocharging system:

Following the instructions provided in the turbocharging system kit, install the new turbocharger, intake pipes, exhaust pipes, etc., in the correct sequence. Ensure that all parts are properly connected, and fasten the screws to the specified torque.

5. Performing adjustments and calibration:

After installing the new turbocharging system, you need to adjust and calibrate the turbocharging controller, fuel injectors, and other components to ensure the system works properly and avoid engine damage from excessive turbocharging.

6. Testing and debugging:

Before taking the watercraft out on the water, conduct necessary testing and debugging to ensure the turbocharging system operates smoothly, without any oil leaks or other issues.

Will increasing the impeller affect the supercharger?

Increasing the size of the impeller can have an impact on the turbocharger, but this depends on specific circumstances and design. The turbocharger is a critical component in the turbocharging system, and it increases the intake pressure by rotating the impeller, thereby improving the engine’s intake density and performance.

In theory, enlarging the impeller’s size may provide greater airflow and turbocharging effects, resulting in increased power output. However, this is not a straightforward process; it requires precise engineering design and testing.

Here are some factors that might be affected:

1. Compatibility:

Increasing the impeller size might lead to space limitations. The impeller must fit the existing turbocharger housing and intake duct to ensure proper installation.

2. Power requirements:

Enlarging the impeller size could increase the power needed to drive the impeller. This might necessitate changes to the drive system and turbocharger settings to ensure stable operation.

3. Wear and durability:

A larger impeller might subject the impeller and related components to higher loads and forces. Ensuring that the impeller and its parts have sufficient strength and durability is essential to prevent premature wear or damage.

4. Aerodynamics:

Increasing the impeller size may impact the turbocharger’s aerodynamic performance, potentially leading to flow instability or decreased efficiency.

5. Temperature and thermal management:

A larger impeller could generate more heat, so considerations for the turbocharger’s thermal management system are necessary to prevent overheating of the engine and turbocharger.

What are the requirements for boosting jet ski performance on a supercharger repair kit?

To enhance the performance of a personal watercraft, it’s usually necessary to use a turbocharger repair kit to increase the engine’s intake density, providing more oxygen and fuel for greater power output. When using a turbocharger repair kit, the following important requirements should be noted:

1. Compatibility:

Ensure the purchased turbocharger repair kit is fully compatible with your personal watercraft model and engine. Different models and brands may require different types of turbocharging systems, so selecting the appropriate repair kit is crucial.

2. Quality and reliability:

Choose a reliable turbocharger repair kit to ensure stable and long-term operation, avoiding mechanical failures or safety issues.

3. Installation and adjustment:

When installing the turbocharger repair kit, strictly follow the detailed installation guidelines provided by the manufacturer. Proper installation and adjustment are key to ensuring the turbocharging system works correctly. If you lack relevant skills and experience, it’s best to seek assistance from professionals.

4. Testing and calibration:

After installation, conduct necessary testing and calibration to ensure the stability and performance of the turbocharging system. This helps detect potential issues and make adjustments.

5. Safety:

Increasing the power output through turbocharging may affect the watercraft’s handling, especially during high-speed operations. Therefore, it’s important to ensure the watercraft remains safe and stable after the turbocharger upgrade. Drive cautiously and familiarize yourself with the new performance characteristics.

In conclusion, enhancing the performance of a personal watercraft is a complex task, especially when modifying the turbocharging system. If you are interested in upgrading your watercraft, feel free to contact us for high-performance parts. We are always ready to assist you.

Recommended Articles

How To Upgrade The Supercharger wheel On Your Sea-Doo Personal Water Craft?

Boost Your Performance with the Seadoo 300 Supercharger Wheel

Exploring Turbocharging Technology in Watercraft Engines

Check this: Impotence Medication: The Ultimate Guide to Treatment, Options, and Expert Advice