To upgrade a Sea-Doo engine to higher horsepower involves wheel modifications, here are some possible modifications:

1. Research and select a suitable aftermarket supercharger wheel:

Look for reputable manufacturers or suppliers that offer upgraded supercharger wheels specifically designed for your Sea-Doo model. Consider factors such as materials, design, and performance specifications to find a wheel that meets your requirements.

2. Gather the necessary tools:

Before starting the upgrade process, ensure you have the appropriate tools for the job. This may include wrenches, sockets, screwdrivers, pliers, and any other tools required to access and replace the supercharger wheel.

3. Disconnect the battery:

For safety purposes, disconnect the battery to prevent accidental electrical issues during the upgrade process.

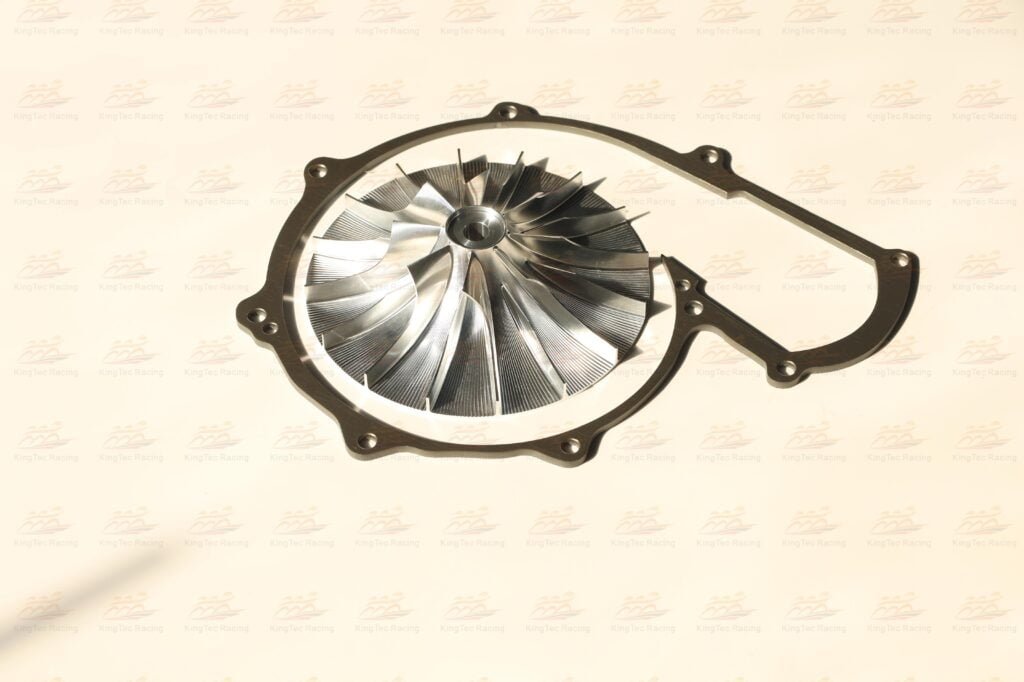

4. Access the supercharger unit:

Locate the supercharger unit on your Sea-Doo personal watercraft. It is typically located near the engine compartment. You may need to remove some components, such as the intake manifold or airbox, to access the supercharger unit.

5. Remove the existing supercharger wheel:

Carefully remove the bolts or fasteners securing the current supercharger wheel to the supercharger shaft. Take note of the orientation and placement of any washers or spacers during the removal process.

6. Install the upgraded supercharger wheel:

Place the new supercharger wheel onto the supercharger shaft, ensuring it aligns correctly with the drive system. Follow any specific instructions provided by the manufacturer regarding installation techniques, torque specifications, and the use of any additional components.

7. Reassemble the supercharger unit:

Once the new supercharger wheel is securely in place, reassemble the supercharger unit by attaching any removed components, such as the intake manifold or airbox, and reconnecting any hoses or electrical connections that were disconnected during the disassembly process.

8. Reconnect the battery:

After completing the reassembly, reconnect the battery to restore power to the personal watercraft.

9. Test and tune:

Start the engine and test the performance of your Sea-Doo personal watercraft. Pay attention to any unusual noises, vibrations, or changes in performance. It is recommended to consult a professional or perform a performance tune-up to optimize the engine’s performance and ensure everything is functioning correctly after the supercharger upgrade.

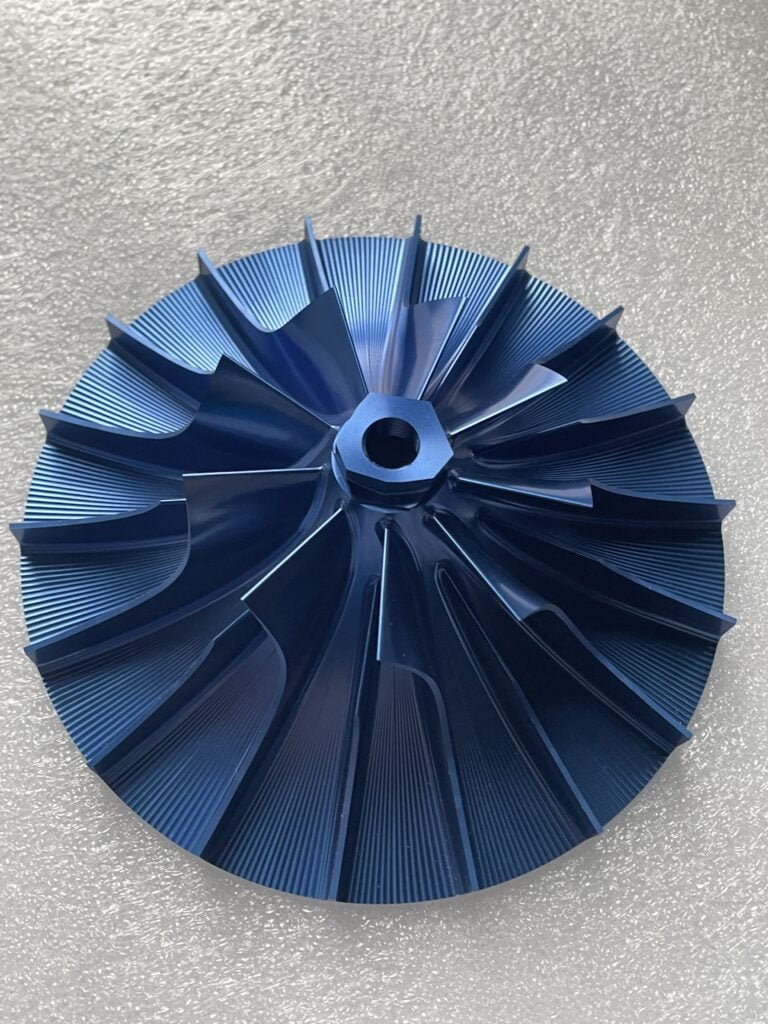

In response to the Seadoo jet ski wheel, is it better with or without the nut?

Here are some considerations for wheels with and without nuts:

1. Safety

Wheels with nuts are better secured to the shaft, reducing the risk of loosening and falling off. This is particularly important as jet skis are subject to high vibrations and shocks at high speeds and during intense water activities.

2. Ease of maintenance

Wheels with nuts allow for easier maintenance and replacement. The nut provides a simple fixation, making it easy to replace or adjust the Wheel when it needs to be changed or adjusted.

3. Prevents loosening

Watercraft wheels can be subjected to significant forces and vibrations during high speed operation and strenuous activity.Wheels with nuts are better able to withstand these forces and vibrations and prevent the wheel from loosening or falling off.

4. Mounting Stability:

Wheels with lug nuts generally provide better stability when mounted. The nut helps to align the impeller with the shaft and maintain the correct mounting position, ensuring optimum performance and thrust output.

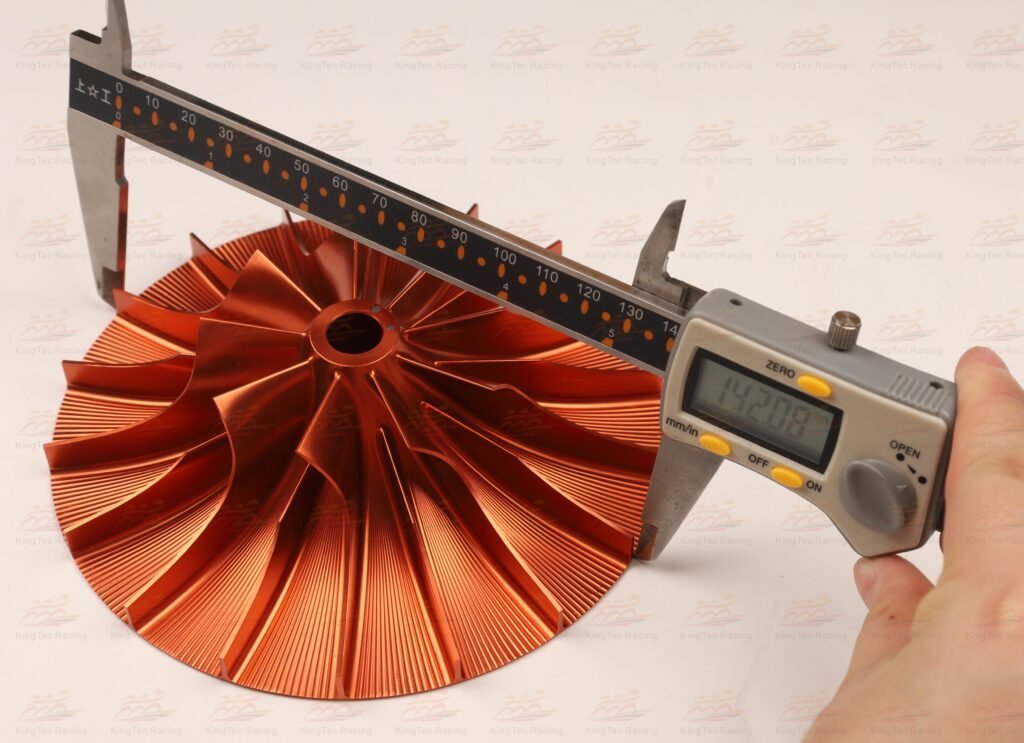

For Seadoo 215/255/260 137mm wheel

Do wheels with screw nut perform better?

From a performance standpoint, a studded wheel will not directly provide higher thrust or horsepower output. The performance of an wheel is largely dependent on its design, materials and hydrodynamic properties.

However, the role of the nut on the wheel is to ensure that the wheel remains stable and securely fastened during high speed rotations and aggressive motion. The nut prevents the impeller from loosening, falling off or drifting off-axis and reduces vibration and noise, thus providing more stable operation and higher reliability.

By providing a stable installation and reducing the risk of the wheel loosening, the nut maintains the wheel in optimum performance condition and prevents possible damage or failure. This ensures that the geometry and hydrodynamic properties of the impeller are maintained to achieve the desired thrust and performance output.

Of course, everyone’s needs are different and if you have a better suggestion you can find us to talk about it. We’re here to support you.